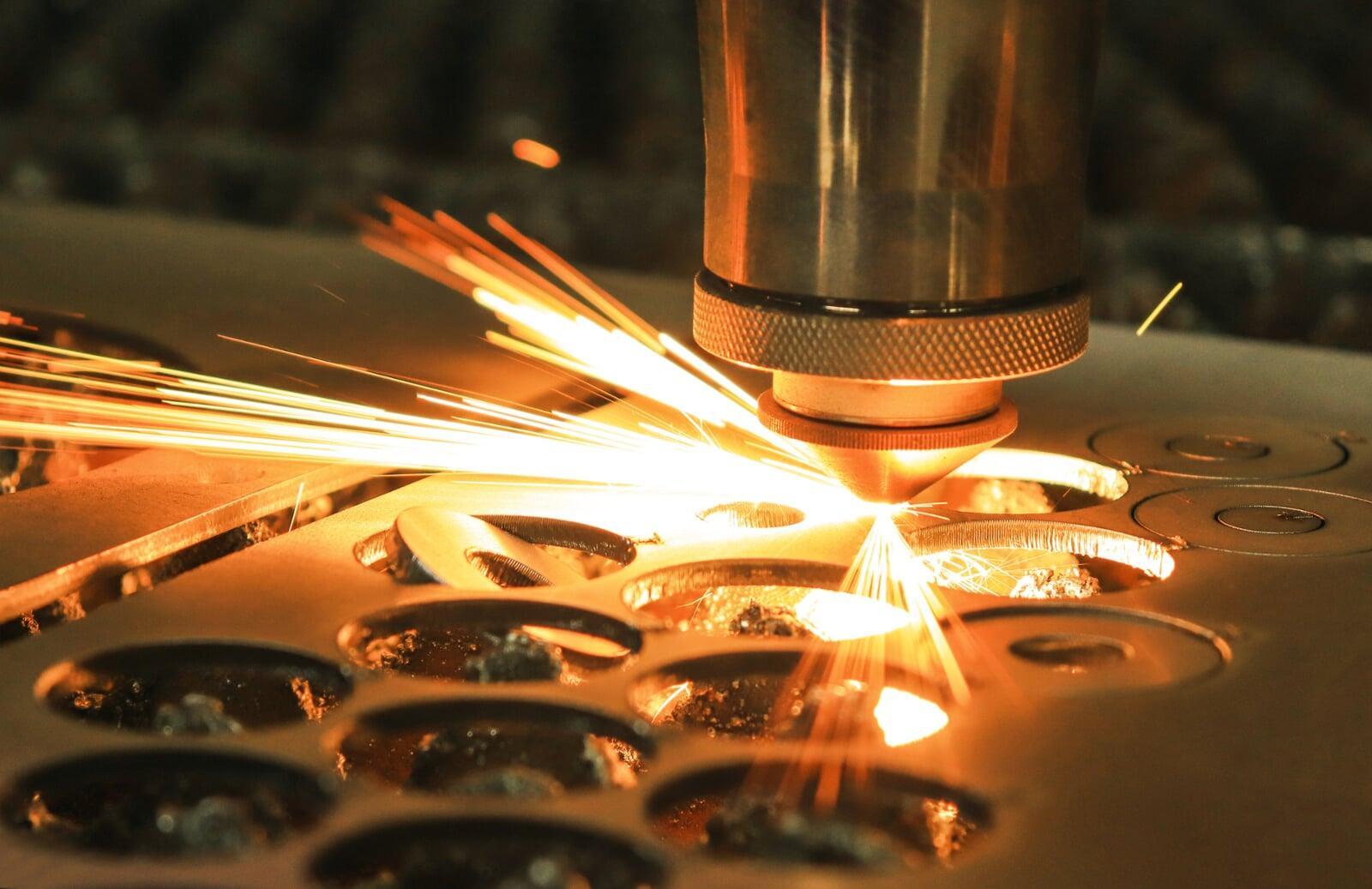

Precision laser cutting

- Achieve Tolerances as tight at ±0.1 mm

- High-power fiber laser optimized for steel, stainless steel, and aluminium.

- Full 8ft x 4ft sheet handling capability.

- Micro-burr edges and low HAZ (heat affected zone) for cleaner finishes.

- We also support custom kerf compensation based on material thickness.

- Nesting optimization to reduce scrap and sheet wastage.

Bending and Forming

- CNC press brake bending up to 3–4 mm steel sheets (typical).

Achievable bend angle accuracy ±0.5° depending on material.

±0.2 mm bend line repeatability with proper datum.

Radius bending + air bending + bottom bending supported.

We can help redesign flat patterns to eliminate extra welds and improve manufacturability.

Fixtures/jigs available for repeat bends in higher quantities.

Welding

- MIG and TIG welding capability for steel and stainless steel.

Welds finished to clean cosmetic surface where required.

Fixtures and clamps used for precision weld alignment and reduced distortion.

We can fabricate full sub-assemblies, not just individual parts.

Surface finishing support: deburring, brushing, minor grinding.

Inspection of critical welds by gauge/fixture when needed.

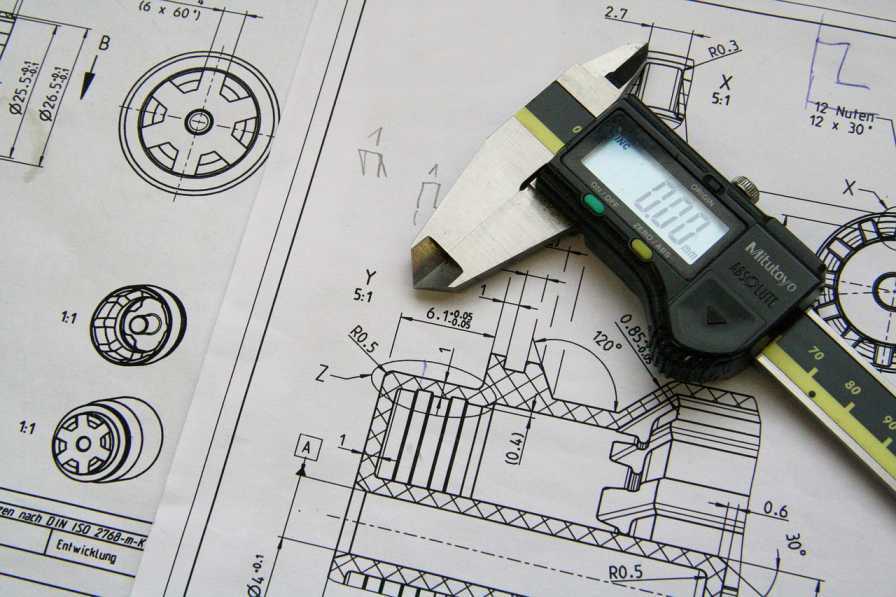

Design and Add-on services

We can convert hand sketches or DXF files into manufacturable CAD models. Full DFM (Design for Manufacturability) feedback to reduce cost and simplify production. We can suggest material thickness, bend relief, bend radii, hole-to-edge spacing, etc. Powder coating, deburring, threading & PEM hardware installation available through partner network. Every part inspected before dispatch for dimensional and visual quality